Thank you for Subscribing to Construction Business Review Weekly Brief

The Point Of Change In The Building Design And Construction Industry

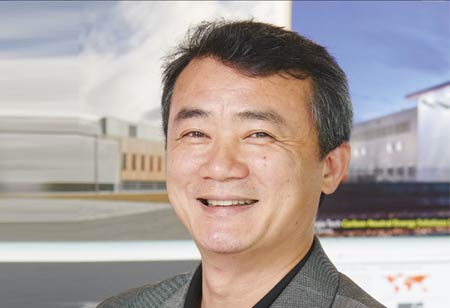

Anationally recognized leader in federal facility design, J.J. Tang, FAIA, FSAME, Vice President and Director of Federal Facilities, has led design of many key federal facilities with combined construction value exceeding billions of dollars, across four continents in the past two decades. As a business executive, he has successfully led and pursued key program initiatives in the past 16 years and has propelled his organization to the forefront of the industry.

Tang was elevated to College of Fellows of American Institute of Architects (FAIA) in 2017, became the second Chinese American FAIA who immigrated from P.R. China. Tang is 2016 recipient of SAME (Society of American Military Engineers) President’s Medal for his outstanding leadership in advancing architectural practice; 2011 SAME Urbahn Medal awarded annually to one architect nationwide for notable and eminent contribution in the field of architecture. His project experience spans various building types including intelligence facilities, secure operations, headquarters, research, laboratories, higher-education, civic, offices, housing, airport facilities. He is an author of numerous technical articles and is a frequent speaker at national conferences. His work has received many honors, and it has been widely publicized.

Here is the conversation that we had with Tang.

What are some of the major challenges and trends that have been impacting the Construction Industry lately?

High inflation and supply chain issue are the two most urging challenges facing the entire construction industry. We are having to work twice as hard to keep projects within budget because of these two issues. Another trend is that sustainable design is now more about “regenerative design.” The term “regenerate” describes a process that mimics nature itself by restoring or renewing its own sources of energy and materials. HDR has developed its own Regenerative Design Framework, an online interactive tool to help us achieve regeneration on all of our projects. Looking into aspects of Triple Net-Zero (energy, water and waste), Carbon Balancing (embodied and operational carbon), Health and Wellness Design, Materials Transparency (manufacturers disclosing the environmental, health and social impacts of their products), Resiliency, and Social Equity.

More and more attention is being paid to adaptive reuse or rejuvenating existing building through SRM funds (facility sustainment, restoration and modernization). The greenest approach to building design is to give a brand-new life to an aging building!

Can you tell us about the latest project that you just completed and what are some of the technological and process elements that you leveraged to make the project successful?

We recently completed a $1.3B, 916,000 SF major command and control HQ facility for DoD. It was completed in 2020 after a decade of design and construction. As described by Deputy Secretary of Defense David L. Norquist, the building is “one of the most complex construction projects in our government’s history.” The reason is not because the above ground building that you can see, rather the underground facility, which posed a lot of challenges to the design team and required a unique and technologically innovative approach. Underground components called for a complete physical and visual inspectable space surrounding the shielded portion of the operation.

A box-withina-box design facilitated the requirements, along with mitigating another issue — a water table that is higher than the occupied floors. The final solution consists of a permanent earth retention system (PERS) along with a duplex pumping system that backs up any groundwater that may occur through hydrostatic pressure. The sophisticated engineering solution provides an annular space for utility routing, and again provides an inspectable space and serves a dual functional role that ordinarily would not be provided. Together with my HDR colleague Mike Doiel, and US Army Corps of Engineers Matt Bird, I authored an article titled “Designing a National Asset,” which was published in the Nov/Dec. 2022 issue of The Military Engineer (TME) magazine that talks about the design of this project in detail. The article received the 2022 Toulmin medal and the project won a 2022 national design award merit award from the Society of American Military Engineer.

Another project is a Navy SEALS Desert Warfare Training Complex in the remote desert of southern California. It was just completed in 2022. Every time I think about it, there is just an immense sense of pride of what we do as architects and engineers for our national security. We were given a lofty goal: deliver the project within an extremely tight budget in a logistically challenged location and do so without sacrificing any mission or program requirements. The HDR team was able to achieve design excellence under extreme budget pressure delivering creativity and innovation, functionally and aesthetically. We employed a mission-centric and function-driven design, partnering with the Naval Facilities Engineering Command Southwest, working directly with the Navy Special Warfare Command to achieve success on this important project.

What are some of the technological or process trends which excite you for the future of the Construction Industry?

One trend I am very excited about, and I think it is a win-win for owners, contractor and AE firms, is the increasing utilization of the Integrated Project Delivery – or IPD – delivery model. Under an IPD agreement, the owner, contractor, major subcontractors, and AE designers are all joined together under a single agreement. Everybody has skin in the game and incentive to deliver the project under the targeted success matrix.

A win-win for owners, contractors, and AE firms is the increasingly utilization of the Integrated Project Delivery — or IPD -- model

The collaboration and creativity fostered by IPD contracts are especially valuable now as design teams need to be highly innovative to solve the challenges created by inflation and the supply chain issues mentioned earlier.

We have completed a number of IPD projects and have found that they enhance communication, collaboration, efficiency; increase everyone’s desire to seek the best throughout the project’s phases; and help ensure respect for team members. IPD projects deliver higher quality, and increased profits to all parties. I truly believe this is a game changer for the design and construction industry, especially for more complex projects.